Understanding the Control Valve Body: Essential Insights for Automotive Professionals

The automotive industry is a complex network of components that work together to ensure each vehicle operates efficiently and reliably. Among these critical components, the control valve body plays a pivotal role in the functionality of automatic transmissions. In this article, we will delve deep into what a control valve body is, its functions, importance, and why it matters for automotive enthusiasts and professionals alike.

What is a Control Valve Body?

The control valve body is a sophisticated assembly found in automatic transmissions that directs hydraulic fluid to various parts of the transmission. It acts as the central nervous system of the transmission system, controlling the flow of fluid based on the driver's input, therefore influencing the transmission's behavior.

Key Functions of the Control Valve Body

- Fluid Distribution: The primary function of the control valve body is to distribute hydraulic fluid to the gears and clutches, enabling smooth shifting in an automatic transmission.

- Pressure Regulation: It also regulates the pressure within the transmission system, ensuring that all components receive the correct amount of fluid under varying operating conditions.

- Shift Control: The valve body is responsible for controlling the timing and sequence of shifts based on various input signals, including throttle position and vehicle speed.

- Error Detection: Many modern valve bodies have the ability to detect errors in the system, sending information to the vehicle’s computer for diagnostics.

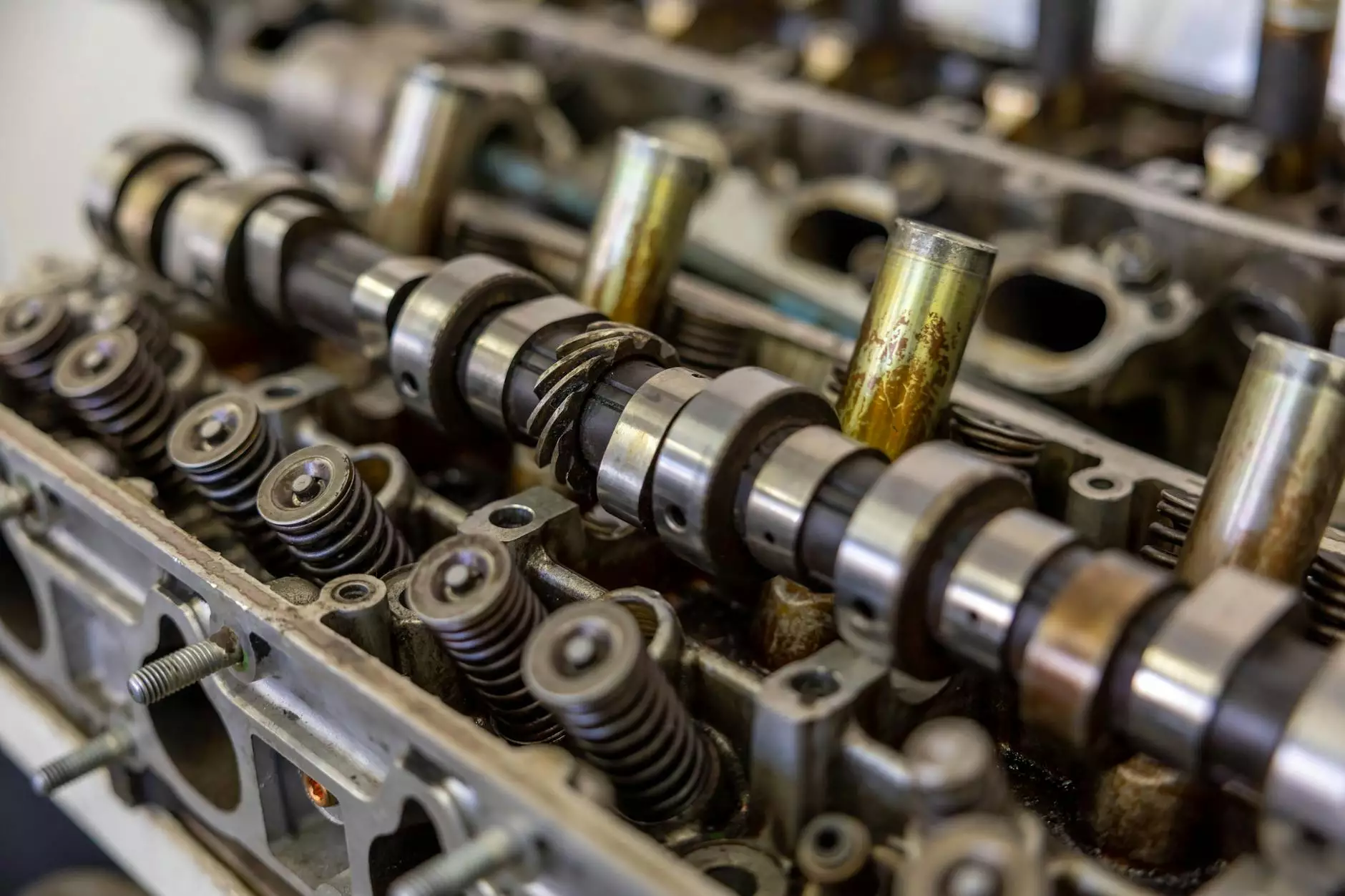

Components of a Control Valve Body

Understanding the components of a control valve body is essential for troubleshooting and maintenance. The typical structure includes several key parts:

- Valves: These are the moving parts that control the flow of hydraulic fluid within the system.

- Passages: Internal channels that allow the hydraulic fluid to travel to the necessary components.

- Sensors: Many valve bodies incorporate sensors that monitor various parameters and send signals to the vehicle's electronic control unit (ECU).

- Electrical Connectors: These facilitate communication between the valve body and other electronic components of the transmission.

Importance of the Control Valve Body in Automotive Performance

The control valve body is integral to the overall performance of a vehicle's transmission. An underperforming or faulty valve body can lead to significant issues, including:

- • Delayed Shifting: A sluggish response when changing gears can cause driver frustration and reduce vehicle control.

- • Harsh Shifts: Unstable shifting can lead to a jerky driving experience and may damage transmission components over time.

- • Poor Fuel Efficiency: An economic vehicle may suffer higher fuel consumption if the transmission is not functioning correctly.

- • Check Engine Light Activation: A malfunctioning control valve body can trigger the vehicle's diagnostics and illuminate warning lights.

Common Issues Associated with Control Valve Bodies

As with any component in a vehicle, the control valve body can encounter various issues. Recognizing these problems early can lead to more efficient repairs and longer vehicle life:

1. Wear and Tear

Over time, constant use and exposure to high pressures can lead to wear on the internal components of the valve body. This can cause:

- • Inconsistent Shifting: Irregular changes in gears regardless of driver's input.

- • Fluid Leaks: Potential leaks due to compromised seals and gaskets.

2. Contamination

Debris and metal particles from the transmission can contaminate hydraulic fluid, leading to:

- • Clogged Passages: Restricted fluid flow that can severely impede performance.

- • Overheating: Excessive heat generation within the transmission due to insufficient lubrication.

3. Electrical Failures

Modern control valve bodies often integrate electronics that can fail due to moisture or corrosion, potentially leading to:

- • Loss of Control: Inability to accurately control shifts or engage clutches.

- • Diagnostic Trouble Codes: Triggers of fault codes that may stop the vehicle's operation.

Maintenance Tips for the Control Valve Body

Proper maintenance of the control valve body is crucial for ensuring the longevity and efficiency of the transmission system. Here are key maintenance tips to consider:

Regular Fluid Changes

Regularly changing the transmission fluid is essential in preventing contamination and ensuring smooth operation. It is vital to:

- • Follow the manufacturer's recommended service intervals.

- • Use high-quality transmission fluid that meets OEM specifications.

Monitor for Warning Signs

Be vigilant for any signs of transmission issues, including:

- • Slipping gears

- • Unusual noises during shifts

- • Warning lights on the dashboard

Consult with Professionals

When in doubt, consult with professionals who have experience in transmission service. They can provide:

- • Diagnostic services to identify issues accurately.

- • Expert repairs to ensure workmanship is up to industry standards.

Conclusion

The control valve body is an essential component of automotive transmissions that significantly impacts vehicle performance and driver experience. Understanding its role, potential issues, and maintenance strategies can help vehicle owners and automotive professionals maintain optimal operation. As the industry evolves with new technology, staying informed will ensure that vehicles run smoothly and efficiently, paving the way for an improved driving experience.

For More Information

If you're looking for high-quality control valve body parts or automotive supplies, visit shenghaiautoparts.com for a comprehensive selection tailored to your automotive needs.